Sustainable Development of Anova Lighting

With the continuous rapid economic development, the increasing shortage of natural resources and severe climate change, we can only achieve a virtuous cycle of society and economy by conserving resources and protecting the environment.

As a manufacture of lighting products, Anova not only needs to ensure market share expansion and profit growth, but also needs to simultaneously optimize the allocation of internal resources to keep up with changes in the external environment. It is part of our mission to use natural resources and energy wisely to increase profitability and scale our business in a sustainable manner.

How to be sustainable in Anova Lighting?

Anova practices sustainability in design, manufacturing, supplier selection, and employee work. Whether it's our engineers considering the materials used in the design of our products or the suppliers of our packaging materials, we are committed to the concept of sustainability.

What Anova Lighting does for sustainability?

Energy Saving

We design and manufacture our downlights with a greater emphasis on the lifetime of the downlight, because a longer lifetime means a lower carbon footprint. Frequent replacement increases resource consumption during manufacturing, packaging and shipping, while LED downlights can last up to 50,000 hours, which reduces resource consumption during manufacturing, packaging and shipping.

In order to reduce the use and waste of paper, our company has adopted K3, OA, and Lark systems, so that employees can work and coordinate through the system to save the use of office paper. At the same time, Anova colleagues, when using paper, collect the paper that has been used up and blank pages continue to be used.

Design

Our company also incorporates environmentally friendly materials when researching new products in order to reduce carbon emissions.

For example, for the DL61601 product, Anova's engineers considered using clad aluminum as the main body of the product from the very beginning of the product design. The outer layer of this thermal material is made of high thermal conductivity plastic, and the inner layer is made of aluminum, fully considering and combining the advantages of plastic and aluminum. At the same time, this heat sink material is cheaper compared to aluminum, and it can also be recycled. The use of plastic to reduce carbon emissions, compared to other materials of the same type will be better to reduce carbon emissions, more in line with the requirements of sustainability. The "plastic-metal" hybrid thermal material can pass safety certification because of its plastic insulation properties, while the back cover of this product is made of thermally conductive nylon, a thermally conductive mud dragon material can reduce carbon emissions.

In addition to the DL61601, when designing the ALSD2535E and ALSD2565E products, Anova's designers also took a new approach on these two products by adding eco-friendly materials plus shellac on the back cover of these two products.

Supply Chain

When we choose our own supply chain, we also choose to work with suppliers that are in line with sustainable development.

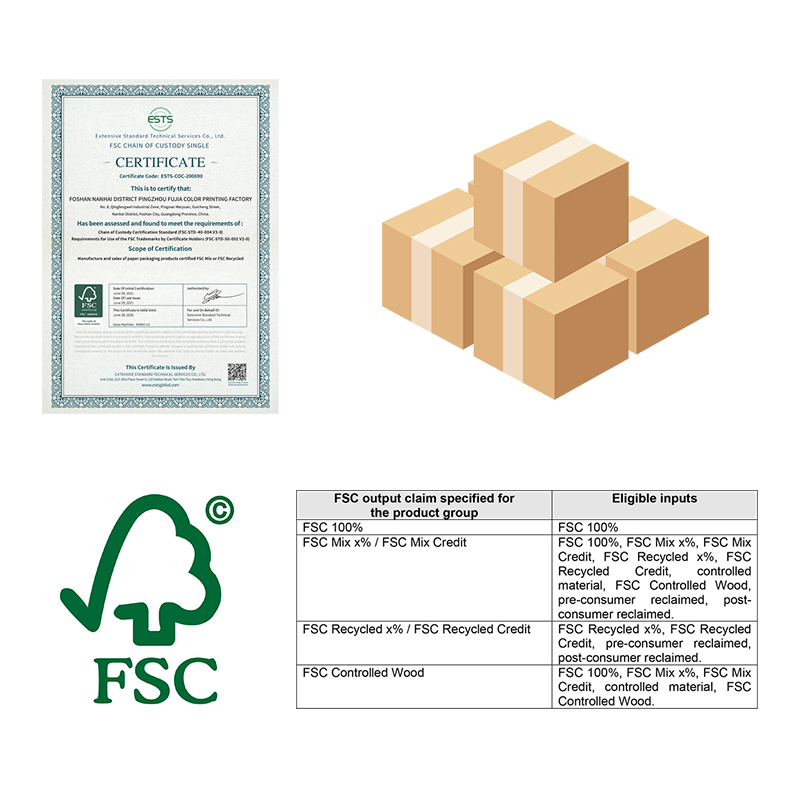

For example, Anova outer packaging materials are FSC certified packaging materials. FSC is a chain-of-custody standard that tracks wood products from the forest to the consumer by setting standards for good forest practices and for the production and marketing of wood processing, so legal and sustainable sources of wood can be controlled.

In addition to the outer box packaging material, the plastic used in our inner packaging, is also a recyclable plastic.